The global High Power Connectors Market is entering a decade of sustained expansion, driven by rapid electrification, renewable energy integration, and the increasing power density of industrial systems.

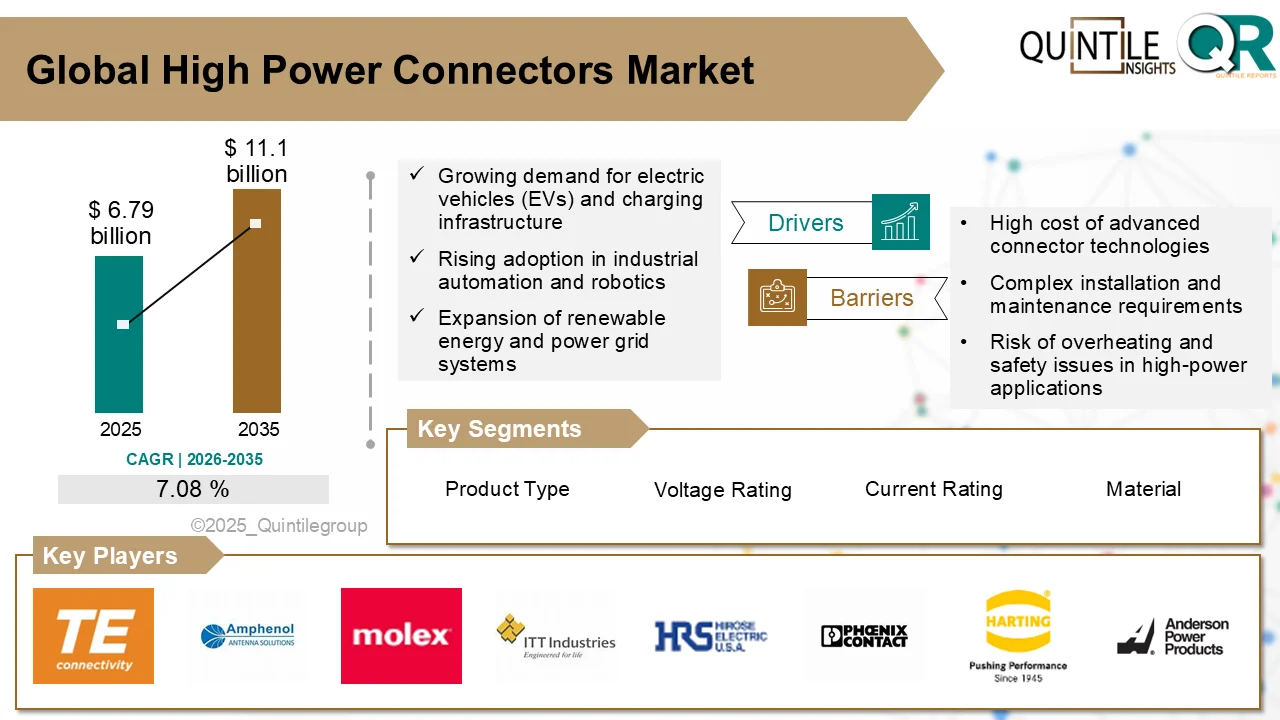

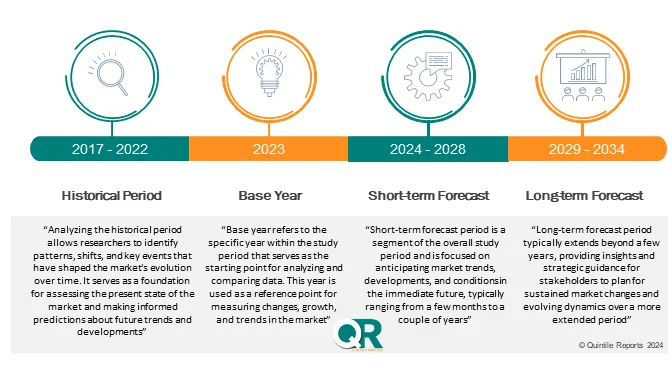

According to the latest analysis by Quintile Research, the market was valued at USD 6.79 billion in 2025 and is projected to reach USD 11.1 billion by 2035, reflecting a steady compound annual growth rate (CAGR) of 7.08% during the forecast period from 2026 to 2035.

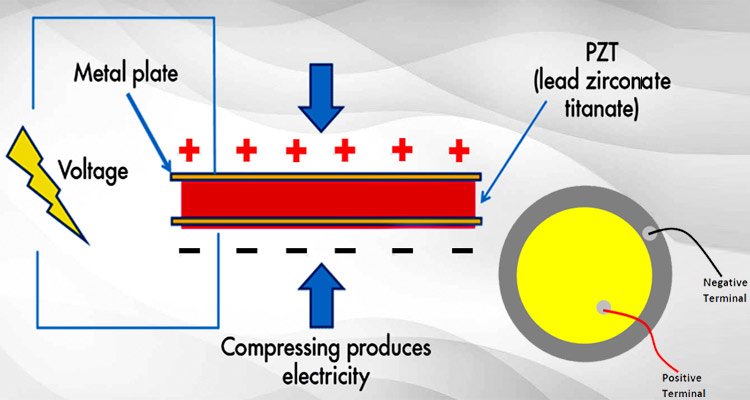

High-power connectors are specialized electrical components engineered to handle high current loads—often exceeding 100 amperes—and elevated voltage levels under demanding operating conditions. Unlike conventional connectors, these solutions are built with enhanced thermal management, robust mechanical integrity, vibration resistance, and long-term durability. They are critical in sectors where reliability, safety, and performance under heavy electrical stress are non-negotiable.

Request Sample PDF Report: https://www.quintilereports.com/request-sample/1150-high-power-connectors-market/

Electrification Driving Core Demand

One of the strongest growth catalysts is the electrification of transportation. The accelerating adoption of electric vehicles (EVs), electric buses, heavy-duty commercial fleets, and next-generation mobility platforms has significantly increased the need for connectors capable of supporting battery systems, inverters, traction motors, and DC fast-charging units. Many of these systems operate above 500A, demanding connectors with superior conductivity, minimal contact resistance, and advanced arc-protection mechanisms.

Discount Request: https://www.quintilereports.com/request-discount/1150-high-power-connectors-market/

Renewable energy expansion is another major growth driver. Solar farms, wind turbines, hydrogen systems, and high-voltage DC transmission networks rely on rugged connectors that can withstand harsh environmental conditions such as humidity, salt exposure, vibration, and temperature fluctuations. As governments worldwide intensify clean energy commitments, demand for reliable high-power electrical interfaces continues to rise.

Industrial automation and digital infrastructure also play a vital role. Industry 4.0 adoption, robotics deployment, CNC machinery, and high-capacity data centers powered by AI and cloud computing require stable, continuous high-current connectivity. Modular power shelves, busbar systems, and backup power infrastructure depend heavily on advanced connector technologies that ensure fault tolerance and operational continuity.

In aerospace and defense, electrification trends are reshaping aircraft systems, unmanned platforms, naval vessels, and ground vehicles. High-power connectors enable the transition from hydraulic and pneumatic systems to electrically driven components, requiring lightweight yet thermally stable and vibration-resistant designs.

Buy Now:- https://www.quintilereports.com/request-enquiry/1150-high-power-connectors-market/

Market Challenges and Competitive Pressures

Despite promising growth, the market faces challenges. The use of premium conductive materials such as silver-plated copper and specialized thermoplastics raises manufacturing costs. Supply chain volatility related to copper, aluminum, and rare-earth materials can impact pricing and availability. Furthermore, strict compliance standards—including UL, IEC, RoHS, REACH, automotive ISO, and aerospace certifications—extend development cycles and increase testing requirements.

Price competition from emerging manufacturers also places pressure on established brands, pushing innovation in modular design, miniaturization, eco-friendly materials, and smart connectors with embedded monitoring sensors.

Regional Growth Patterns

North America remains a strong growth region, supported by electric vehicle infrastructure expansion, power grid modernization, and data center growth. Europe’s momentum is tied to decarbonization mandates, offshore wind development, and hydrogen initiatives, with Germany leading innovation in connector engineering. Asia-Pacific is the fastest-growing region, fueled by large-scale manufacturing, renewable energy deployment, and smart city projects in China, Japan, and South Korea. Meanwhile, Latin America and the Middle East & Africa are experiencing rising demand linked to solar investments, infrastructure development, and grid upgrades.

Competitive Landscape

The market is characterized by strong competition and technological differentiation. Leading companies such as TE Connectivity, Amphenol Corporation, Molex LLC, Phoenix Contact, and HARTING Technology Group continue to invest in advanced materials, high-current miniaturization, and digital-enabled connector systems. Innovation focuses on thermal efficiency, modular architectures, and predictive maintenance capabilities.

Outlook Through 2035

Looking ahead, the High Power Connectors Market is expected to maintain consistent growth momentum. Electrification, renewable expansion, AI-driven infrastructure, and evolving defense systems will continue to expand application areas. Companies that prioritize R&D, supply chain resilience, and regulatory compliance will be best positioned to capitalize on emerging opportunities.

As global systems become increasingly power-intensive, high-power connectors will remain foundational components enabling safe, efficient, and reliable energy transmission across industries.

Electrification Trends Boosting the High Power Connectors Market

The rapid expansion of electric vehicles (EVs), commercial electric fleets, and charging infrastructure is a primary driver of the High Power Connectors Market. These connectors are essential for battery packs, power inverters, traction motors, and DC fast-charging systems operating at high amperage levels.

The global push toward decarbonization and renewable energy integration is further fueling the High Power Connectors Market. Solar farms, wind energy systems, and high-voltage DC transmission grids require robust connector solutions capable of handling extreme environmental conditions.

Industrial Automation Expanding the High Power Connectors Market Scope

Industry 4.0 adoption, robotics deployment, and high-capacity data centers are contributing significantly to High Power Connectors Market growth. As manufacturing plants increase power density and automation, demand for reliable, high-performance connectors continues to rise.

Additionally, aerospace and defense electrification trends are expanding the High Power Connectors Market, with increasing requirements for lightweight, vibration-resistant, and thermally stable connector systems.

1. What is the High Power Connectors Market?

The High Power Connectors Market refers to the global industry focused on designing, manufacturing, and supplying electrical connectors capable of handling high current (typically above 100A) and high voltage applications. These connectors are widely used in electric vehicles, renewable energy systems, industrial automation, aerospace, defense, and power infrastructure.

2. What is the projected growth of the High Power Connectors Market?

The High Power Connectors Market was valued at USD 6.79 billion in 2025 and is projected to reach approximately USD 11.1 billion by 2035, growing at a CAGR of 7.08% during the forecast period from 2026 to 2035.

3. What are the key drivers of the High Power Connectors Market?

Major growth drivers of the High Power Connectors Market include:

-

Rapid adoption of electric vehicles (EVs)

-

Expansion of renewable energy infrastructure

-

Growth in data centers and AI-driven computing

-

Industrial automation and Industry 4.0

-

Grid modernization and high-voltage transmission projects

4. Which industries use high power connectors?

The High Power Connectors Market serves several industries, including:

-

Automotive (especially EVs and hybrid vehicles)

-

Renewable energy (solar, wind, hydrogen systems)

-

Industrial manufacturing and robotics

-

Aerospace and defense

-

Data centers and telecommunications

5. Who are the key players in the High Power Connectors Market?

Leading companies operating in the High Power Connectors Market include TE Connectivity, Amphenol Corporation, Molex LLC, Phoenix Contact, and HARTING Technology Group. These companies focus on product innovation, high-current miniaturization, and smart connector solutions.

6. What challenges affect the High Power Connectors Market?

The High Power Connectors Market faces challenges such as:

-

High raw material costs (copper, silver plating)

-

Strict compliance and certification standards

-

Supply chain volatility

-

Increasing price competition

-

Thermal management and miniaturization constraints

7. Which region dominates the High Power Connectors Market?

North America and Europe hold strong positions in the High Power Connectors Market due to EV adoption and renewable investments, while Asia-Pacific is the fastest-growing region driven by large-scale manufacturing, infrastructure expansion, and smart city projects.

8. Why is electrification important for the High Power Connectors Market?

Electrification is a primary growth catalyst for the High Power Connectors Market because electric vehicles, battery storage systems, and renewable power plants require connectors capable of handling high current loads safely and efficiently.

Our latest Publication

High Power Connectors Market (2026 – 2035)

Our Latest News:

Moisture Curing Adhesive Market to Reach USD 12.62 Billion by 2034 Driven by Construction and Automotive Demand

Adarsh

Business Strategy — Quintile Reports

Adarsh is a Business Strategy professional focused on transforming market insights into actionable growth plans. He supports strategic initiatives through market analysis, competitive intelligence, and data-driven decision-making to help drive long-term business success.

His core skills include strategic planning, market research, growth opportunity assessment, trend analysis, performance tracking, stakeholder communication, cross-functional collaboration, and critical problem-solving.