The global Bin Picking System market is entering a phase of accelerated growth, driven by rapid advancements in robotics, artificial intelligence (AI), and machine vision technologies.

As industries worldwide face mounting labor shortages, rising operational costs, and increasing pressure to improve productivity, bin picking systems are emerging as a critical automation solution across manufacturing, logistics, and warehousing environments.

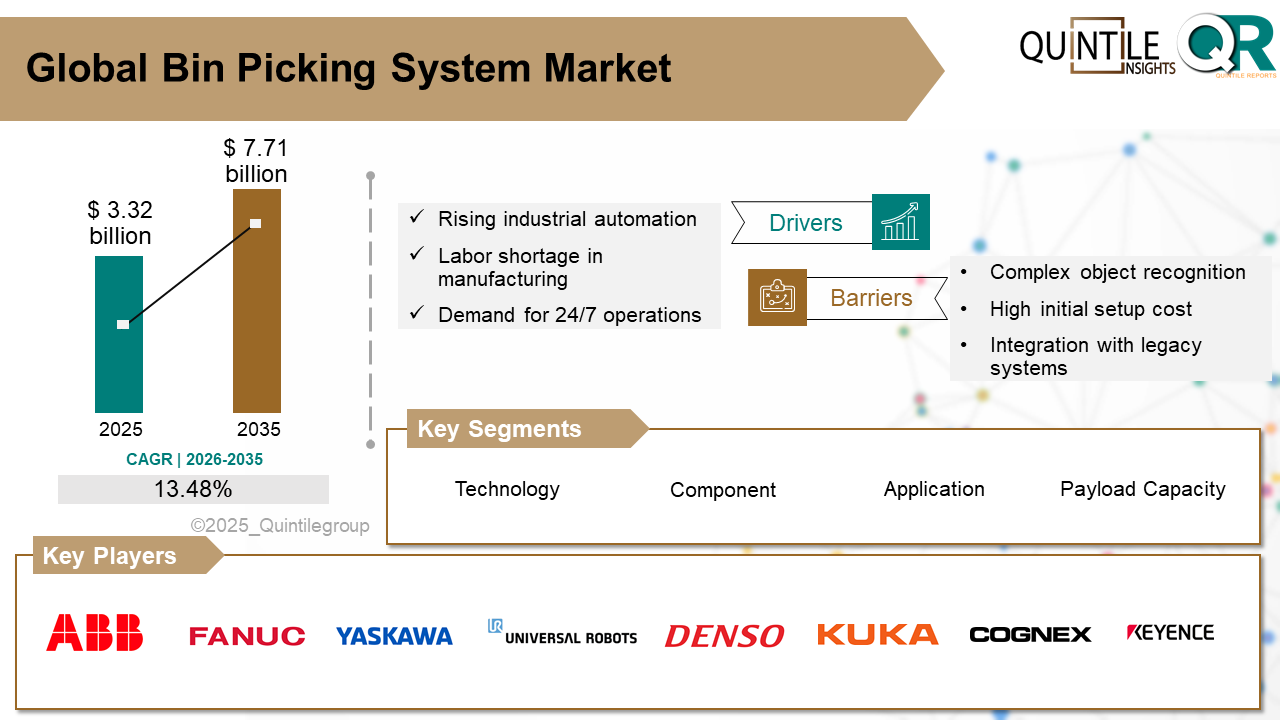

According to Quintile Research, the global Bin Picking System market was valued at USD 3.32 billion in 2025 and is projected to reach USD 7.71 billion by 2035, expanding at a robust CAGR of 13.48% during the forecast period from 2026 to 2035. This strong growth trajectory reflects the increasing adoption of intelligent automation solutions that enable robots to identify, select, and retrieve randomly placed objects from bins with high precision and reliability.

From Traditional Automation to Intelligent Bin Picking

Bin picking systems represent a significant evolution in industrial automation. Early systems relied largely on 2D vision technologies, which offered limited depth perception and struggled with overlapping or randomly oriented objects. Modern bin picking solutions, however, integrate 3D computer vision, AI-driven perception, and advanced robotics, enabling accurate detection of object position, orientation, and accessibility even in highly cluttered environments.

Request sample PDF Report: https://www.quintilereports.com/request-sample/1222-bin-picking-system-market/

Technologies such as stereo cameras, structured light, and laser triangulation generate detailed depth maps, while AI-based grasp planning algorithms determine the most efficient and collision-free picking paths. Combined with sophisticated end-of-arm tooling (EOAT) such as suction grippers and adaptive multi-finger grippers, these systems are now capable of handling complex materials, including reflective metals and transparent plastics.

Key Drivers Fueling Market Growth

One of the primary drivers of the bin picking system market is the global labor shortage, particularly in repetitive, physically demanding industrial tasks. Rising wages, demographic shifts, and workforce constraints are pushing manufacturers and logistics operators toward automation that supports lights-out operations, improves consistency, and enhances workplace safety.

The rapid expansion of e-commerce and omnichannel retail has further intensified demand for automated picking solutions. Fulfillment centers are under pressure to process high volumes of mixed SKUs at speed, and bin picking systems offer the scalability and accuracy required to meet these expectations.

Additionally, advances in AI-powered vision systems have significantly improved pick success rates and throughput. Machine learning enables systems to learn from past picks, continuously optimizing performance and reducing error rates. The growing adoption of collaborative robots (cobots) has also lowered the barrier to entry, making bin picking solutions accessible to small and mid-sized enterprises (SMEs) without extensive safety infrastructure or complex programming.

Challenges and Market Constraints

Despite its strong growth outlook, the bin picking system market faces several challenges. Accurate 3D perception remains a technical hurdle, particularly when handling transparent, reflective, or dark-colored objects. Occlusion and object entanglement can complicate segmentation and pose estimation, increasing system complexity.

Integration challenges also persist, as bin picking solutions must seamlessly connect with robots, vision systems, conveyors, and warehouse management software. High upfront investment costs and system customization requirements may limit adoption among cost-sensitive organizations, especially SMEs.

Regional Trends and Competitive Landscape

North America currently leads the market, driven by large-scale automation in e-commerce and logistics. Europe, particularly Germany, is seeing strong adoption of modular, cobot-based systems aligned with Industry 4.0 initiatives. Asia Pacific is emerging as a high-growth region, with countries such as Japan and China deploying AI-enabled bin picking systems across manufacturing and electronics sectors.

The competitive landscape includes global robotics leaders, vision technology providers, and innovative startups focused on AI-driven perception and grasping solutions. Strategic partnerships, R&D investments, and acquisitions continue to shape market dynamics.

Outlook Through 2035

Looking ahead, the Bin Picking System market is set to play a foundational role in the future of smart factories and automated warehouses. Companies that prioritize innovation, flexible system design, and scalable go-to-market strategies are expected to gain a competitive edge in this rapidly evolving market.

As automation shifts from structured environments to handling real-world variability, bin picking systems will remain at the forefront of industrial transformation.

Our Latest Publication

Bin Picking System Market Size Estimation, Share & Future Growth Trends Analysis, By Technology & Vision Type (2D Vision Systems, 3D Vision Systems), By Components & System Type, By Application & Process Type, By Payload Capacity & Working Distance and Regional Analysis, 2026-2035

Our Latest News:

Healthcare Fabrics Market to Reach USD 23.10 Billion by 2034, Driven by Rising Demand for Medical Textiles

Adarsh

Business Strategy — Quintile Reports

Adarsh is a Business Strategy professional focused on transforming market insights into actionable growth plans. He supports strategic initiatives through market analysis, competitive intelligence, and data-driven decision-making to help drive long-term business success.

His core skills include strategic planning, market research, growth opportunity assessment, trend analysis, performance tracking, stakeholder communication, cross-functional collaboration, and critical problem-solving.