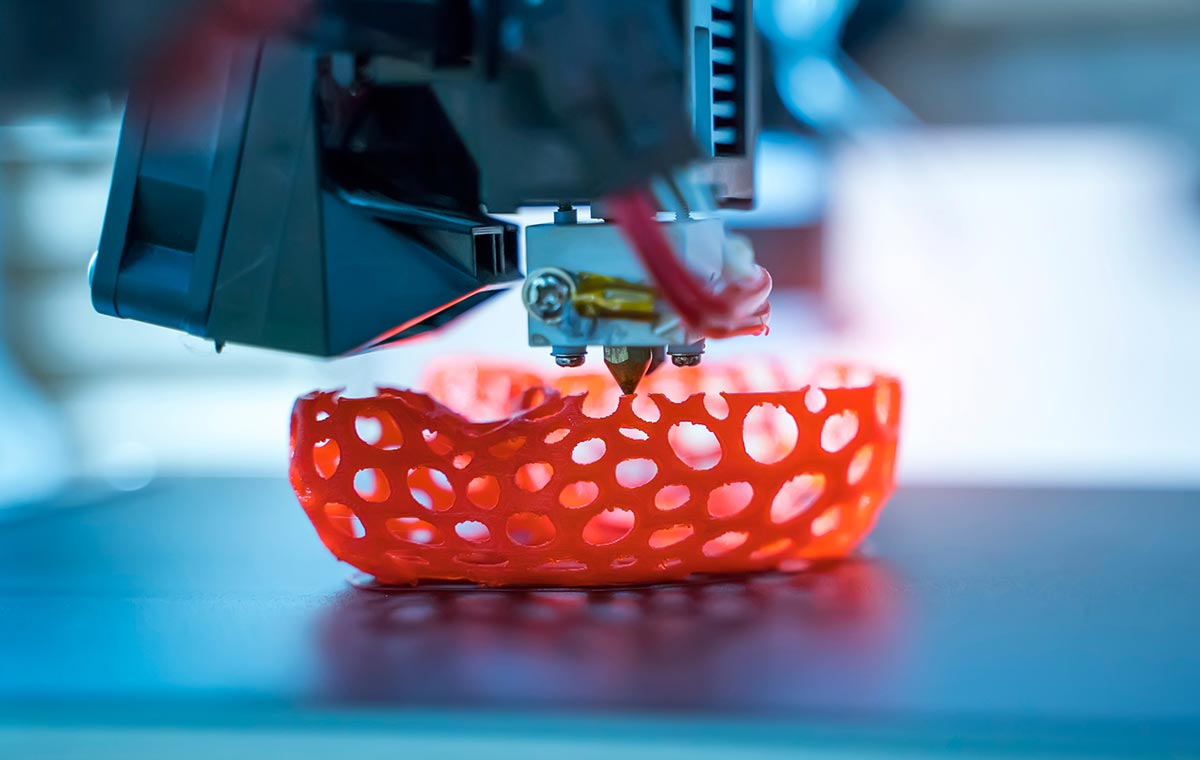

The latest developments in additive manufacturing highlight how 3D printing continues to influence defense readiness, industrial leadership, healthcare innovation, and advanced materials science. From major defense-funded initiatives in the United States to breakthroughs in recyclable metal alloys in Japan, the sector is demonstrating both technological maturity and expanding real-world impact.

A key announcement came from America Makes, the U.S. Department of Defense–supported manufacturing innovation institute, which revealed the winners of its $1.1 million Project Call under the Allied Additive Manufacturing Interoperability (AAMI) Program. The initiative, delivered in partnership with the National Center for Defense Manufacturing and Machining (NCDMM), aims to strengthen interoperability between U.S. and UK defense supply chains. Lockheed Martin is leading one project team alongside ASTM International and Additive Manufacturing Solutions, Ltd., while Eaton Corporation is heading a second team that includes EOS North America, Materials Solutions (a Siemens Energy business), and 3Degrees.

Funded by the Office of the Under Secretary of Defense for Research and Engineering’s Manufacturing Technology Program, the AAMI initiative focuses on laser powder bed fusion (LPBF) 3D printing of critical defense components. The program seeks to overcome shared challenges faced by allied nations, including secure data exchange, intellectual property protection, material qualification, and supply chain resilience. By aligning with both the U.S. Regional Sustainment Framework and the UK Advanced Manufacturing Strategy, the selected teams will identify technical and regulatory barriers while supporting the development of internationally harmonised qualification approaches for metal additive manufacturing.

Industry leadership developments also marked the week. Austal USA, a prominent shipbuilder and contributor to the U.S. Navy’s submarine industrial base, appointed Dan Brintzinghoffer as Vice President for Business Development and External Affairs, effective February 9. Brintzinghoffer succeeds Larry Ryder and brings decades of naval and defense-sector experience. His background includes service as Commanding Officer of the USS Pinckney and as Executive Assistant to the Assistant Secretary of the Navy for Research, Development, and Acquisition. Most recently, he served as Senior Vice President of Growth and Strategy at Leidos’ Defense Systems Sector, where he helped secure more than $11 billion in new business and expand capabilities in areas such as hypersonics, space sensing, and maritime systems. Austal USA leadership noted that his expertise will support the company’s long-term growth and expanding maritime programs.

Standards development, a critical pillar of additive manufacturing adoption, also saw a leadership transition. ASTM International announced that Amer Bin Ahmed has begun his term as Chair of its Board of Directors. The ASTM board oversees more than 12,000 global standards spanning multiple industries. Bin Ahmed brings nearly two decades of experience in sustainability, industrial manufacturing, and standards-based innovation, particularly in the gypsum and construction materials sectors. Previously serving as Vice Chair, he has led business operations across Africa, Asia, and the Middle East, and has been actively involved in ASTM initiatives related to advanced and additive manufacturing, including additive construction projects and public-sector collaborations in regions such as Dubai and India.

Beyond defense and standards, additive manufacturing is also reshaping sports medicine. PROTECT3D, a North Carolina–based company founded by former Duke University football players Kevin Gehsmann, Clark Bulleit, and Tim Skapek, is using 3D printing to produce custom orthotics and braces for injured athletes. By combining biomechanics expertise with digital scanning and additive manufacturing, the company delivers personalised medical devices within roughly 48 hours. Professional teams across the United States have adopted these solutions, enabling faster recovery and return-to-play timelines. PROTECT3D now aims to extend its services beyond professional sports to broader healthcare and military communities.

On the materials front, researchers at Nagoya University in Japan reported the development of a new family of heat-resistant, recyclable aluminum alloys specifically designed for metal 3D printing. Traditional aluminum alloys lose strength at high temperatures, limiting their use in engines and turbines. The research team leveraged the unique rapid cooling conditions of laser powder bed fusion to stabilise novel microstructures, incorporating elements such as iron, manganese, titanium, and copper. One standout composition—an aluminum–iron–manganese–titanium alloy—demonstrated both room-temperature flexibility and high-temperature strength, while remaining easier to print than conventional high-strength aluminum alloys. Importantly, the materials are recyclable and use relatively low-cost elements, supporting sustainability goals.

Together, these developments underscore how additive manufacturing is evolving across defense, industry leadership, healthcare, and materials science. As standards mature, leadership strengthens, and new applications emerge, 3D printing continues to move closer to large-scale, mission-critical adoption across multiple sectors.

Our Latest News

https://www.quintilereports.com/industry-report/1040-3d-printed-brain-model-market/

Adarsh

Business Strategy — Quintile Reports

Adarsh is a Business Strategy professional focused on transforming market insights into actionable growth plans. He supports strategic initiatives through market analysis, competitive intelligence, and data-driven decision-making to help drive long-term business success.

His core skills include strategic planning, market research, growth opportunity assessment, trend analysis, performance tracking, stakeholder communication, cross-functional collaboration, and critical problem-solving.